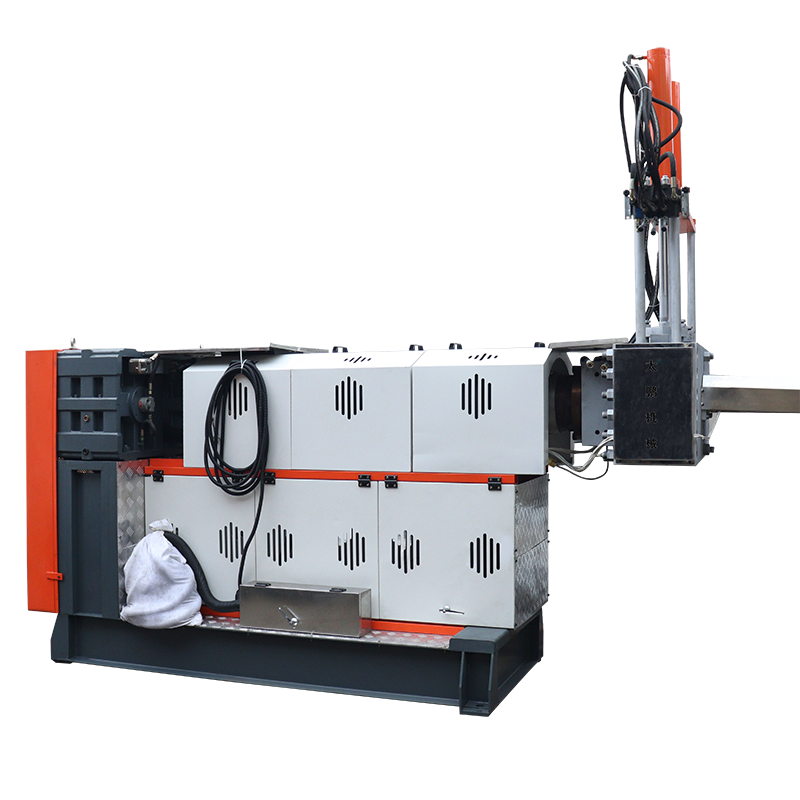

PE.PP pulverizer machine High Output Plastic Grinding Mill Machine

Plastic Processed: PE/PP, ABS

Condition: New

Output (kg/h): 100 - 150 kg/h

Video outgoing-inspection: Not Available

Machinery Test Report: Provided

Warranty of core components: 1 Year

Core Components: Gearbox, Motor

Place of Origin: Zhejiang, China

Brand Name: TP

Type: Granulating Production Line

Screw Design: Single

Voltage: customized, Customized

Dimension(L*W*H): 4500*1200*1200mm

Power (kW): 75KW

Weight: 6

Warranty: 1 Year

Showroom Location: Egypt, Turkey, Russia

Applicable Industries: Manufacturing Plant, Farms, Home Use, Energy & Mining

Gearbox: Hard-teeth

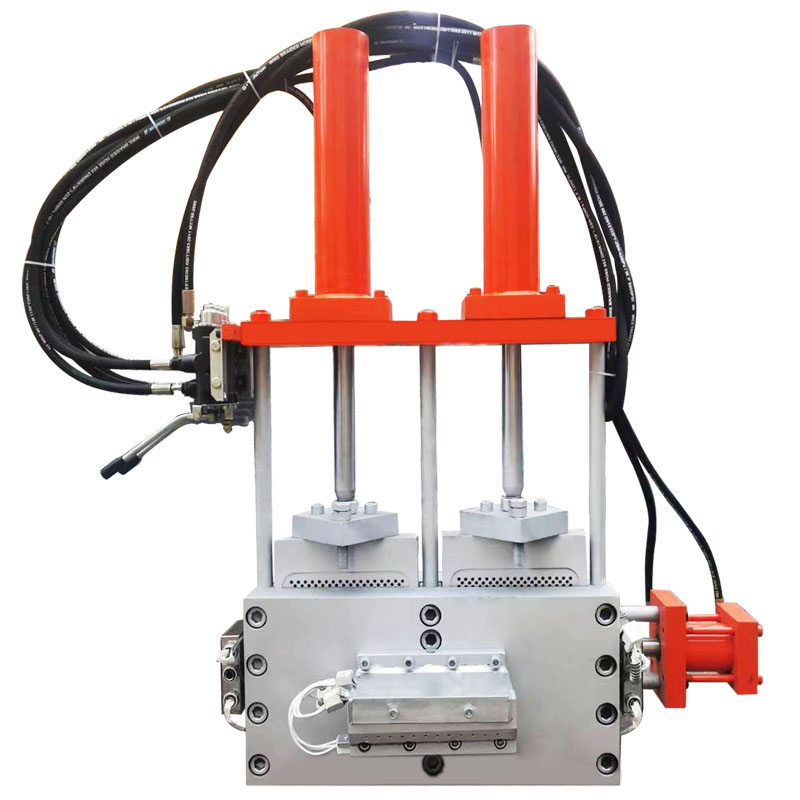

Mould: Hydraulic filter changer

Color: Customized

Heating method: Cast-Al heating

Capacity: 20 sets/ month

Power: Customized

Name: Plastic Granulator Machine

Function: Plastic Rcycling

Material: 38CrMoALA

Marketing Type: Ordinary Product

(1) The granulator must be operating positively; reversal should be avoided.

(2) In order to prevent the stick bar phenomena, the pelletizer must be operated with hot machine feeding and is not permitted to run empty (holding shaft).

(3) Inserting iron or other foreign objects into the granulator's feed inlet or vent hole is strictly prohibited. in order to prevent unneeded mishaps that could compromise safety and regular production.

(1) Pay close attention to any changes in the fuselage's temperature. The strip should be heated as soon as a clean hand touches it without touching it. Before the note reaches hands, everything is normal.

(2) The reducer must be promptly stopped down for repair and topped off with oil if the bearing portion burns or is accompanied by noise.

(3) Stop the machine for maintenance and lubricate the bearing components when they burn your hands or produce noise at each end of the main engine bearing chamber. The bearing chamber should be placed every 5 to 6 days during regular operation, and butter should be added once.

(4) Pay attention to the machine's operating rules. For instance, if the machine's temperature is high or low and its speed is rapid or slow, the problem can be handled appropriately at the appropriate moment.

(5) If the fuselage is unsteady, pay close attention to see if the connection fitting's clearance is too tight and make the necessary adjustments.