Granulating machine for ps recycled scrap Extruding ldpe pelletizer line

Place of Origin: Ningbo

Brand Name: TP

Condition: New

Material: PP

Spare Parts Type: Machiine spares

Warranty: 1 Year

Key Selling Points: Competitive Price

Applicable Industries: Manufacturing Plant, Retail

Showroom Location: Egypt, Turkey, Saudi Arabia, Indonesia, Mexico, Russia, Algeria

After-sales Service Provided: Free spare parts, Video technical support, Field maintenance and repair service, Online support

Local Service Location: Egypt, Turkey, Brazil, Peru, Indonesia, Mexico, Morocco

After Warranty Service: Video technical support, Online support, Spare parts

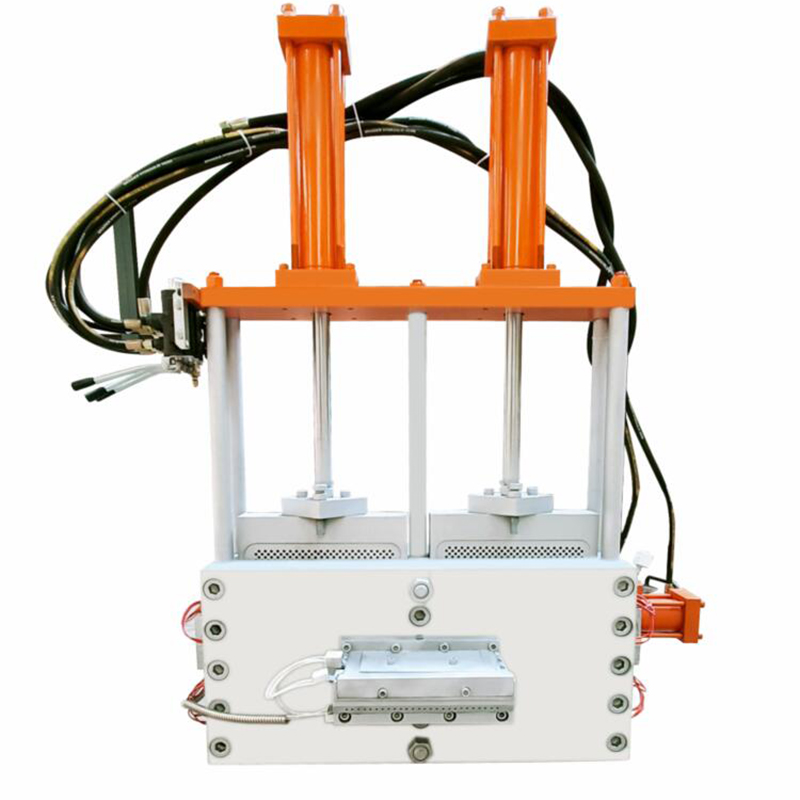

Product name: Screen Changer Die Head

(1) The granulator should be in positive operation; Avoid reversing.

(2) The pelletizer is forbidden to operate without load, and must be operated with hot machine feeding, so as to avoid the phenomenon of stick bar (holding shaft).

(3) It is strictly forbidden to enter iron and other sundries in the feed inlet and vent hole of the granulator. In order to avoid unnecessary accidents and affect the safety and normal production.

1. The angle of the granulator can be adjusted. The appropriate angle can reduce the thickness of the material, thus realizing the screening of ultra-thin layers. It should be noted that when the feed speed is too high, it will cause material accumulation, which will not only reduce the screening efficiency, but also may cause damage to the screen.

2. Increase the power of granulator motor. The motor provides support for the screening work and is the main force of the complete screening work. Proper adjustment of the motor power can also improve the output of the granulator.

3. Adjust the number of granulator grids. There must be more than these reasons that affect the productivity of the granulator. Relatively speaking, these methods are more practical and most effective. It is also possible that these methods are not suitable for your company's current situation. You can contact our company's technical personnel. We will develop special solutions based on your problems to reduce unnecessary losses for you.