PE/PP pulverizer machines play a vital role in transforming plastic recycling. They reduce waste into fine, uniform particles, making handling and processing easier for manufacturing plants, farms, and energy operations. These machines lower energy use by up to 50% and cut transportation volume, which decreases emissions and costs. The PE.PP pulverizer machine High Output Plastic Grinding Mill Machine supports the circular economy by converting waste into reusable materials. Plant managers and engineers see immediate gains in efficiency and product quality with the PE.PP pulverizer machine High Output Plastic Grind.

Key Takeaways

- PE/PP pulverizer machines turn plastic waste into fine, uniform powder, improving recycling efficiency and product quality.

- These machines reduce energy use by up to 50%, lowering operational costs and environmental impact.

- Automation and advanced features minimize downtime and labor needs, boosting productivity and safety.

- Consistent particle size from pulverizers ensures better moldability and stronger, defect-free plastic products.

- Pulverizers help reduce landfill waste by increasing material density and enabling more efficient transport and storage.

- Using recycled powder lowers demand for virgin plastics, supporting a circular economy and reducing pollution.

- Modern pulverizer machines integrate easily with existing recycling lines, streamlining workflows and saving time.

- Investing in high-quality pulverizer machines opens new market opportunities and increases profitability for recycling businesses.

Enhanced Material Recovery with PE.PP Pulverizer Machine High Output Plastic Grinding Mill Machine

Maximizing Usable Output

Fine Powder Production

PE/PP pulverizer machines use high-speed disc or blade grinding to transform plastic scrap into fine powder. This process relies on centrifugal force, which breaks down materials efficiently. Built-in sieves and screens ensure that only particles of the desired size pass through, while larger pieces return for further grinding. The PE.PP pulverizer machine High Output Plastic Grinding Mill Machine incorporates an integrated blower system that collects the powder, reducing dust and heat. Cooling systems, such as air or water, prevent heat damage to sensitive plastics. Automation features, including auto feeding and digital control panels, streamline the process and boost productivity. These design elements allow recycling plants to achieve consistent, high-quality powder suitable for manufacturing new products.

Consistent Particle Size

Uniform particle size is essential for downstream manufacturing processes. The PE.PP pulverizer machine High Output Plastic Grinding Mill Machine uses advanced screening equipment to maintain tight control over particle distribution. Consistency in particle size improves moldability and ensures that recycled materials meet industry standards. Integration with shredders, granulators, and drying systems further enhances the quality of the output. This approach reduces downtime and increases the efficiency of pelletizing and extrusion operations.

Tip: Consistent particle size not only improves product quality but also reduces equipment wear and maintenance needs.

Reducing Waste

Lower Landfill Contributions

Implementing PE/PP pulverizer machines in recycling operations significantly reduces the volume of plastic waste sent to landfills. Low-temperature pulverization systems decrease particle size and increase material density. For example, pulverizing marine debris into particles smaller than 5 mm can raise density from 106 kg/m³ to between 420 and 770 kg/m³. This improvement allows for up to seven times more efficient loading and storage. Further compression can increase packing density more than tenfold, making transport and storage more cost-effective.

Improved Resource Utilization

By producing fine, uniform powder, these machines enable recycling plants to recover more usable material from plastic waste. The integration of drying and compaction steps with pulverization ensures that feedstock remains stable and efficient for downstream processes. This approach maximizes the yield from each batch of recycled plastic, reducing the need for virgin materials and supporting a circular economy.

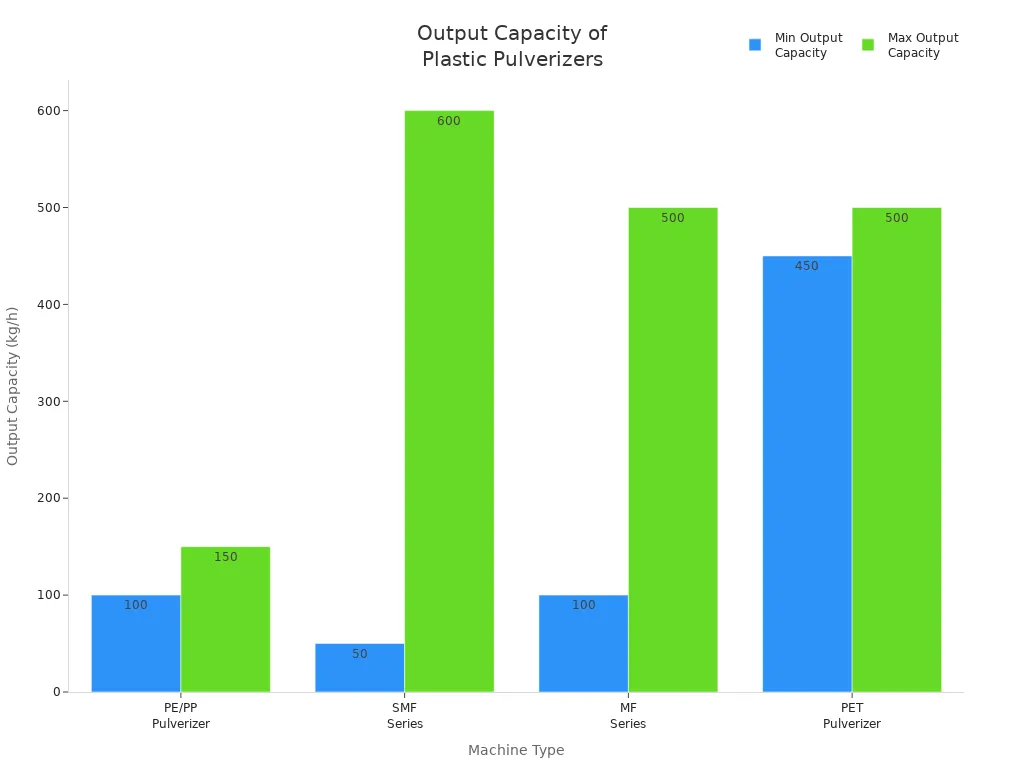

Below is a comparison of output capacities for various types of plastic pulverizer machines:

| Machine Type | Output Capacity (kg/h) | Power (kW) | Notes |

|---|---|---|---|

| PE/PP Pulverizer | 100 – 150 | 75 | Single-stage granulator machine |

| SMF Series Pulverizer | 50 – 600 | 37 – 90.5 | Disc-type pulverizer, model dependent |

| MF Series Pulverizer | 100 – 500 | 30 – 75 | Rotor mill type, model dependent |

| PET Pulverizer (Disc) | 450 – 500 | 75 | High output, disc blade grinding |

The table and chart above show that while PE/PP pulverizer machines may have lower output capacities compared to some disc-type and rotor mill pulverizers, their ability to produce fine, uniform powder and reduce waste volume makes them indispensable for modern recycling operations.

Improved Processing Efficiency in Plastic Recycling Plants

Faster Throughput

High-Speed Grinding Capabilities

PE/PP pulverizer machines deliver significant improvements in processing speed for plastic recycling plants. Advanced models, such as those from Reduction Engineering Scheer and Powder King, achieve higher throughput rates by optimizing tooth configurations and motor-to-disc connections. These enhancements allow plants to process more material in less time, which directly boosts productivity.

| Pulverizer Manufacturer | Throughput / Increase Details |

|---|---|

| Reduction Engineering Scheer | ~15% average throughput increase for temperature-sensitive resins (e.g., PP) |

| Powder King (PKA Velocity) | Up to 2,000 pounds per hour throughput for PE |

| Pallmann Industries (PolyGrinder) | Up to 3,300 pounds per hour throughput for PE and other plastics |

High-speed grinding capabilities, such as those found in the SMF-800 model, support continuous production with output capacities reaching 450-500 kg/h. Direct motor-to-disc connections improve efficiency by approximately 10% compared to traditional belt-driven machines. Optimized air dynamics and advanced cooling systems maintain low operating temperatures, which increases yield by 5-10%. These features enable recycling plants to handle larger volumes of plastic waste efficiently.

Note: High-speed grinding not only increases output but also ensures consistent powder quality, which is essential for downstream manufacturing.

Reduced Downtime

Modern PE/PP pulverizer machines incorporate features that minimize downtime. Easy blade adjustment allows operators to control powder size quickly, reducing the need for lengthy maintenance stops. Integrated monitoring systems, such as bearing temperature sensors and fault warnings, help prevent unexpected breakdowns. Fully sealed grinding chambers prevent dust leakage, creating a safer and cleaner work environment. These design elements ensure reliable, uninterrupted operation and maximize equipment uptime.

Automation and Integration

Compatibility with Existing Lines

PE/PP pulverizer machines offer excellent compatibility with existing recycling lines. Their compact design and modular construction make installation straightforward in manufacturing plants, farms, and energy operations. Automated feeding systems and digital control panels allow seamless integration with shredders, granulators, and drying units. This compatibility streamlines the entire recycling process, reducing manual intervention and improving overall plant efficiency.

Streamlined Workflow

Automation plays a key role in enhancing workflow within recycling facilities. Fully automated designs reduce manpower requirements and enable continuous, dust-free operation. Customizable blades and adjustable grinding parameters provide flexibility for processing different types of plastics. Integrated monitoring and control systems ensure smooth operation and quick response to any issues. As a result, plant managers can achieve higher productivity, lower operational costs, and improved product consistency.

- Continuous production with minimal manual oversight

- Quick changeover between different plastic materials

- Enhanced safety through dust-free, sealed systems

- Real-time monitoring for proactive maintenance

PE/PP pulverizer machines transform plastic recycling plants by delivering faster throughput, reducing downtime, and enabling seamless automation and integration. These advantages position recycling operations for long-term success in a competitive industry.

Superior Product Quality from PE.PP Pulverizer Machine High Output Plastic Grinding Mill Machine

Uniform Powder for Manufacturing

Enhanced Moldability

Manufacturers rely on uniform powder to achieve optimal moldability in plastic products. The PE.PP pulverizer machine High Output Plastic Grinding Mill Machine provides precise control over particle size by allowing operators to adjust grinding parameters such as rotational speed and screen size. This control ensures the production of fine, consistent powder. The advanced grading system within the machine reduces both coarse and excessively fine particles, which improves packing density and enhances the efficiency of heating and melting processes.

- Operators can fine-tune grinding settings for different materials.

- The machine maintains powder uniformity through enclosed design and integrated dust removal.

- Cooling systems prevent overheating, which preserves the quality of sensitive plastics.

Uniform powder distribution leads to consistent wall thickness and improved mechanical properties, such as impact and weather resistance. Fine powder also enhances the surface finish of molded products by reducing defects like “orange peel.” Low-temperature grinding further protects material quality by minimizing thermal degradation and the generation of volatile organic compounds.

Better End-Product Consistency

Consistent particle size plays a critical role in the quality of molded plastic products. Non-uniform powder often results in inconsistent melting and mixing during compounding or rotational molding. The PE.PP pulverizer machine High Output Plastic Grinding Mill Machine produces a fine, homogeneous powder that supports uniform melting and mixing. This uniformity directly contributes to the production of superior, defect-free molded items.

High-quality pulverized resin powder, typically around 35 mesh, is essential for manufacturing defect-free parts. Poorly pulverized powder can cause clumping, leading to flow and fill problems during molding. These issues may manifest as voids, surface porosity, or reduced impact strength. Manufacturers often assess powder quality using a flow test, where an optimal flow time of 22 to 30 seconds indicates good uniformity and supports consistent molding performance.

Uniform powder fineness within the ideal range of 30-40 mesh ensures even spreading and proper filling of molds. This results in consistent wall thickness and smooth surfaces in finished products. The machine’s ability to produce powder with excellent flowability and bulk density helps the powder adhere evenly to mold walls, preventing issues like flying fines or uneven distribution. These features lead to higher product quality, improved production efficiency, and material savings.

Contaminant Removal

Advanced Separation Features

Modern pulverizer machines incorporate advanced separation features to remove contaminants from plastic feedstock. Integrated sieves and air classifiers separate unwanted particles, such as metal fragments or oversized plastic pieces, from the final powder. This process ensures that only clean, high-quality powder moves forward in the manufacturing process.

Note: Effective contaminant removal reduces the risk of defects in finished products and extends the lifespan of downstream equipment.

Higher Purity Levels

Achieving high purity levels in recycled plastic powder is essential for meeting industry standards. The PE.PP pulverizer machine High Output Plastic Grinding Mill Machine uses enclosed grinding chambers and dust extraction systems to minimize contamination during processing. These features help maintain the integrity of the recycled material, resulting in powder with higher purity levels. Manufacturers benefit from improved product reliability and reduced rejection rates, which supports both quality assurance and operational efficiency.

Cost Savings and Profitability for Recycling Operations

Lower Operational Costs

Energy-Efficient Design

PE/PP pulverizer machines feature advanced engineering that prioritizes energy efficiency. Manufacturers equip these machines with high-efficiency motors and optimized cutting mechanisms. These features reduce electricity consumption during operation. Variable speed drives allow operators to adjust the grinding process to match material requirements, further minimizing unnecessary energy use. Many recycling plants report up to 50% lower energy costs after upgrading to modern pulverizer systems. This reduction in power usage directly impacts the bottom line, making recycling operations more sustainable and profitable.

Reduced Labor Requirements

Automation plays a significant role in lowering labor costs. Modern PE/PP pulverizer machines integrate smart technologies such as automated feeding, digital control panels, and real-time monitoring. These features reduce the need for manual intervention. Operators can oversee multiple machines simultaneously, increasing workforce productivity. Automated systems also minimize human error, leading to fewer stoppages and less time spent on maintenance. Recycling facilities benefit from streamlined workflows and lower staffing expenses.

Tip: Investing in automation not only cuts labor costs but also improves workplace safety by reducing direct contact with machinery.

Increased Revenue Opportunities

Value-Added Recycled Products

PE/PP pulverizer machines enable recycling businesses to transform plastic waste into high-quality recycled pellets and powders. These value-added products meet the standards required for use in manufacturing new goods. Companies can sell these materials to industries such as packaging, automotive, and construction. The ability to produce consistent, high-grade recycled plastics opens new revenue streams and increases the overall profitability of recycling operations.

- Recycled pellets and powders command higher prices in the market.

- Consistent product quality attracts more buyers and long-term contracts.

- Enhanced material recovery increases the volume of saleable goods.

Access to New Markets

The demand for sustainable and eco-friendly products continues to rise. Businesses equipped with advanced pulverizer machines gain a competitive edge by supplying recycled PE and PP materials that meet strict environmental standards. Regulatory incentives and global sustainability trends encourage investment in recycling technology. As a result, companies can expand into new markets and industries that prioritize green sourcing.

- Packaging, automotive, and construction sectors seek reliable recycled materials.

- Regulatory support and incentives lower barriers to market entry.

- Future innovations, such as AI-driven optimization, promise even greater revenue potential.

| Opportunity | Description |

|---|---|

| High-quality recycled goods | Sell to manufacturers for premium applications |

| New industry channels | Enter packaging, automotive, and construction markets |

| Regulatory incentives | Benefit from government programs supporting sustainable recycling |

| Technology-driven growth | Leverage automation and smart features for higher productivity and profits |

PE/PP pulverizer machines not only reduce operational costs but also unlock new avenues for revenue. Recycling businesses that invest in these technologies position themselves for long-term growth and profitability in a rapidly evolving market.

Sustainability and Environmental Impact of PE.PP Pulverizer Machine High Output Plastic Grinding Mill Machine

Supporting Circular Economy

Closed-Loop Recycling

PE/PP pulverizer machines play a crucial role in advancing closed-loop recycling within the plastics industry. These machines break down polyethylene and polypropylene waste into fine, reusable powder. This process allows recycling plants to treat plastic waste as a valuable raw material. By converting discarded plastics into high-quality feedstock, companies can reintroduce these materials into new production cycles. This approach reduces landfill waste and supports sustainable development goals. Specialized recycling equipment, such as the PE.PP pulverizer machine High Output Plastic Grinding Mill Machine, enables efficient processing of mixed plastics and additives. As a result, recycling operations can reclaim more material and maintain the mechanical and physical properties needed for new products.

Closed-loop recycling not only conserves resources but also minimizes environmental pollution by keeping plastics in use for longer periods.

Reduced Virgin Plastic Demand

The use of PE/PP pulverizer machines directly decreases the demand for virgin plastic. By transforming post-consumer and post-industrial waste into high-quality powder, these machines provide manufacturers with a reliable alternative to new raw materials. This shift reduces the environmental impact associated with extracting and processing petroleum-based plastics. Recycling plants benefit from lower material costs and improved sustainability metrics. The ability to process a wide range of PE and PP products further enhances the value of recycled materials in the marketplace.

Lower Carbon Footprint

Energy Savings

Modern PE/PP pulverizer machines deliver significant energy savings compared to traditional plastic grinding equipment. For example, a typical crusher and open mill system consumes around 77KW of power, while a new pulverizer uses only 55KW. This difference saves 22KW per hour. In some cases, total electricity usage drops from 110KW to just 40-50KW, resulting in savings of 60-70KW. High-speed, water-cooled grinding wheels and lower operating temperatures further reduce energy consumption. These features allow recycling plants to operate continuously with fewer operators and shorter processing times.

| Aspect | Traditional Equipment | PE/PP Pulverizer Machine | Savings/Benefits |

|---|---|---|---|

| Power Consumption | 77KW | 55KW | 22KW saved |

| Total Electricity | 110KW | 40-50KW | 60-70KW saved |

| Operators Needed | 3 | 1 | 2 fewer operators |

| Capacity | 100 Kg/hour | 120-180 Kg/hour | 20-80 Kg/hour increase |

| Operating Temp | 160°C | ~60°C | Lower temp preserves quality |

Emissions Reduction

Lower energy consumption leads to reduced greenhouse gas emissions. The PE.PP pulverizer machine High Output Plastic Grinding Mill Machine operates at lower temperatures, which helps preserve material quality and minimizes the release of volatile organic compounds. Efficient processing and reduced reliance on virgin plastics further decrease the carbon footprint of recycling operations. By enabling the reuse of plastics and supporting closed-loop systems, these machines help companies meet environmental targets and contribute to a cleaner planet.

Recycling facilities that invest in advanced pulverizer technology demonstrate leadership in sustainability and environmental stewardship.

How to Choose the Right PE.PP Pulverizer Machine High Output Plastic Grinding Mill Machine

Selecting the ideal PE.PP pulverizer machine High Output Plastic Grinding Mill Machine requires careful evaluation of several factors. The right choice ensures efficient recycling, consistent product quality, and long-term operational reliability.

Key Selection Criteria

Capacity and Throughput

Every recycling operation has unique production demands. Operators must assess the daily output requirements before choosing a machine. A model with insufficient capacity can create bottlenecks, while an oversized unit may waste energy. Leading manufacturers offer machines with a wide range of throughput, from small-scale to industrial levels. Matching machine capacity to plant needs ensures smooth workflow and optimal resource use.

Material Compatibility

Not all pulverizer machines handle every type of plastic equally well. Operators should confirm that the chosen machine processes the specific grades of polyethylene (PE) or polypropylene (PP) used in their facility. Versatile machines accommodate a broader range of plastics, supporting future expansion and changes in feedstock. Material compatibility also affects the consistency and reusability of the recycled powder.

Tip: Always verify that the machine can process both current and anticipated plastic types to maximize investment value.

Evaluating Machine Features

Safety Mechanisms

Safety remains a top priority in any industrial setting. Modern pulverizer machines incorporate advanced safety features, such as emergency stop buttons, interlocked covers, and overload protection. These mechanisms protect operators and help facilities comply with industry regulations. A machine with robust safety systems reduces the risk of accidents and supports reliable, long-term operation.

Maintenance Requirements

Ease of maintenance directly impacts machine uptime and operational costs. Machines designed with accessible parts and user-friendly interfaces simplify routine servicing. Quick-change blades, clear maintenance schedules, and intuitive controls allow technicians to perform tasks efficiently. Reduced downtime translates to higher productivity and lower repair expenses.

| Feature | Benefit |

|---|---|

| Accessible components | Faster maintenance |

| User-friendly controls | Simplified operation |

| Durable construction | Longer service life |

Supplier and Support Considerations

After-Sales Service

Strong after-sales support ensures continued machine performance. Buyers should evaluate the supplier’s reputation for technical assistance and the availability of local service engineers. Prompt support minimizes production interruptions and helps resolve issues quickly. Many suppliers provide video support, long-term service agreements, and on-site engineering for overseas customers.

Warranty and Spare Parts

A comprehensive warranty offers peace of mind and protects against unexpected costs. Most manufacturers provide a one-year warranty, covering essential repairs and replacements. Ready access to spare parts, especially critical components like blades and screens, further reduces downtime. Reliable suppliers maintain a robust inventory and deliver parts quickly to keep operations running smoothly.

Note: Choosing a supplier with a strong track record and responsive support team can make a significant difference in long-term operational success.

PE/PP pulverizer machines stand out as indispensable assets in modern plastic recycling plants. They deliver enhanced material recovery, improved processing efficiency, superior product quality, cost savings, and strong sustainability outcomes. Operators report greater reliability and durability, especially when handling dirty plastics. Regular maintenance and proper usage extend machine life and reduce downtime. These advantages help plant managers achieve consistent performance and long-term operational success.

Decision-makers seeking to boost efficiency and sustainability should consider integrating advanced pulverizer technology into their recycling operations.

FAQ

What types of plastics can a PE/PP pulverizer machine process?

PE/PP pulverizer machines handle polyethylene (PE) and polypropylene (PP) materials. Many models also process similar thermoplastics, including LDPE, HDPE, and some blends. Operators should always check material compatibility before use.

How often should operators perform maintenance on these machines?

Routine maintenance, such as blade inspection and cleaning, should occur weekly. Operators should follow the manufacturer’s maintenance schedule for optimal performance and longevity.

Can these machines integrate with existing recycling lines?

Most PE/PP pulverizer machines feature modular designs. They integrate easily with shredders, granulators, and automated feeding systems. This compatibility streamlines workflow in recycling plants.

What safety features do modern pulverizer machines include?

Manufacturers equip machines with emergency stop buttons, interlocked covers, and overload protection. These features help protect operators and ensure compliance with industry safety standards.

How does particle size affect the quality of recycled products?

Consistent particle size improves moldability and ensures uniform melting. This leads to higher-quality finished products with fewer defects and better mechanical properties.

What is the typical power consumption of a PE/PP pulverizer machine?

Power consumption varies by model. Most machines use between 30 kW and 75 kW. Energy-efficient designs help reduce operational costs.

Are spare parts readily available for these machines?

Reputable suppliers maintain inventories of critical spare parts, such as blades and screens. Quick access to parts minimizes downtime and supports continuous operation.

How does a PE/PP pulverizer machine support sustainability goals?

These machines enable closed-loop recycling by converting plastic waste into reusable powder. This process reduces landfill contributions and lowers demand for virgin plastics.

Tip: Regular maintenance and proper operation extend machine life and maximize recycling efficiency.

Post time: Aug-06-2025