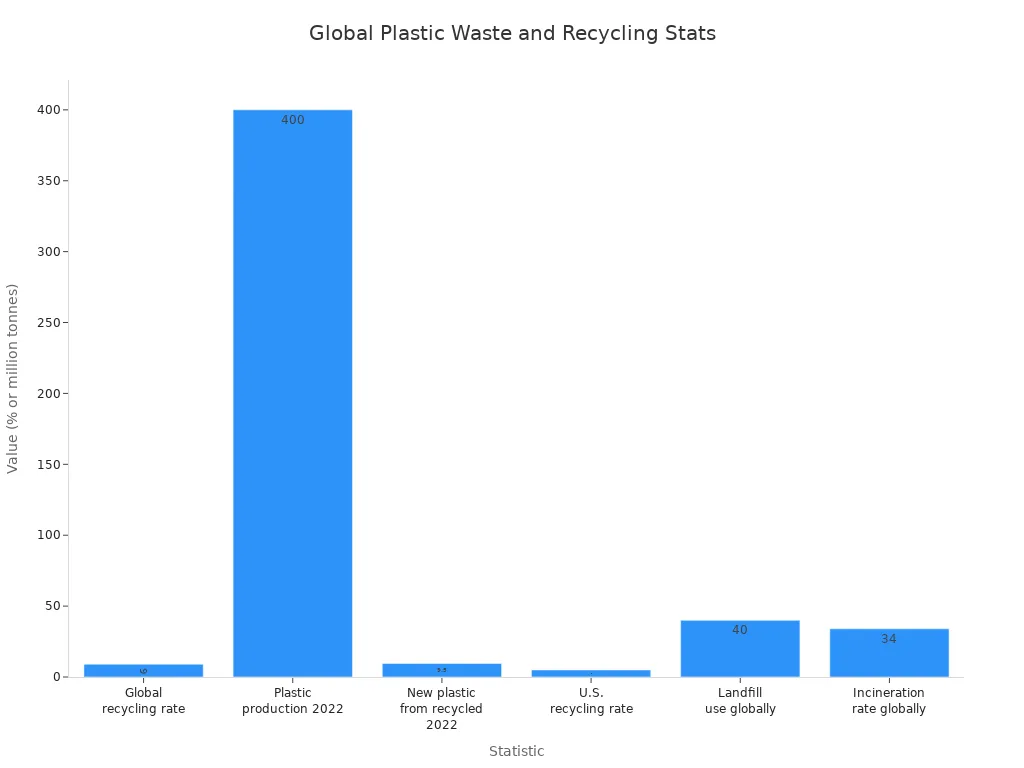

Global plastic recycling rates remain alarmingly low, with only 9% of plastic waste recycled as of 2025. Decision-makers must carefully evaluate their options, as selecting the right New Technology Plastic Recycling Machine can impact both operational efficiency and environmental outcomes.

| Statistic Description | Value / Detail |

|---|---|

| Global plastic recycling rate | Approximately 9% (stagnant as of 2025) |

| Plastic production in 2022 | 400 million tonnes |

| Percentage of new plastic made from recycled materials (2022) | 9.5% |

| U.S. plastic recycling rate | 5% (one of the lowest globally) |

| Landfill use for plastic waste globally | About 40% |

| Incineration rate for plastic waste globally | About 34%, increasing, especially in EU, China, Japan |

| Projection without intervention (2040) | Recycling rates remain below 10% |

| Projection with strong policies (2040) | Recycling rates could rise to 43% |

| Main barriers to recycling | Economic factors, contamination, complexity of plastics |

Key Takeaways

- Choose a recycling machine that matches your plastic waste types and volume to ensure efficient processing and avoid bottlenecks.

- Prioritize energy-efficient machines with smart automation to save costs, reduce environmental impact, and improve productivity.

- Secure strong after-sales support, including maintenance, spare parts, and operator training, to protect your investment and keep operations running smoothly.

Type of Plastic Waste for New Technology Plastic Recycling Machine

Identifying Your Plastic Waste Stream

Selecting the right New Technology Plastic Recycling Machine starts with a clear understanding of the plastic waste stream. Facilities in 2025 encounter a wide variety of plastics. Common types include HDPE, PP, PET, ABS, and PS. Many machines, such as the NGR S:GRAN series, process both rigid and flexible plastics, even when contaminated or containing moisture. Companies like KW Plastics and Biffa focus on HDPE, PP, and PET, highlighting their prevalence in recycling operations. Advanced shredders and pelletizers handle these materials efficiently, while AI-powered sorting systems achieve up to 90% accuracy, reducing contamination and improving output quality.

Tip: Conduct a thorough audit of incoming plastic waste to determine the dominant polymer types and contamination levels.

Matching Machine Capabilities to Material Types

Different plastics require specific recycling technologies. Mechanical recycling works well for PET bottles due to their high collection rates and simple structure. Flexible plastics like LDPE and PP often need advanced chemical recycling, such as pyrolysis or gasification. Mixed or contaminated plastics demand sophisticated separation and chemical treatment. The Recycling Technology Selection Framework (RTSF) helps stakeholders evaluate options by considering economic, technical, and environmental factors. Facilities must ensure machine compatibility with their waste stream, processing capacity, and available space.

- Match machine type to plastic properties and contamination.

- Consider energy efficiency and operational costs.

- Choose compact or industrial-scale models based on facility size.

Adapting to Evolving Plastic Trends in 2025

Plastic waste composition continues to shift. Demand for plastics in packaging, automotive, and healthcare drives the need for adaptable recycling machines. Regional growth, especially in Asia Pacific, increases the variety of polymers processed. New regulations, such as bans on single-use plastics and extended producer responsibility laws, push manufacturers toward recyclable alternatives. Machines must now handle a broader range of polymers, including those with high strength or temperature resistance.

| Polymer | Projected Trend for 2025 | Impact on Machine Selection |

|---|---|---|

| HDPE | Dominant in packaging and infrastructure | Machines must process HDPE efficiently |

| EPDM | Growth in construction and energy sectors | Machines need to handle strong, heat-resistant polymers |

Processing Capacity of New Technology Plastic Recycling Machine

Assessing Current and Future Volume Needs

Determining the right processing capacity remains a critical step when investing in a New Technology Plastic Recycling Machine. In 2025, most advanced machines offer a typical processing capacity of about 300 kilograms per hour. Operators must evaluate both current and projected waste volumes to avoid underutilization or bottlenecks. Manufacturers recommend a comprehensive assessment that includes the type and volume of plastics, matching throughput to operational needs, and considering economic factors such as maintenance and energy consumption. Consulting with suppliers provides valuable insights into machine suitability, while attention to output quality, safety, and available space ensures the equipment fits seamlessly into existing workflows.

Scalability and Flexibility

Modern recycling machines must adapt to changing business demands. Leading models like the JianTai XS-400 and XR-800 demonstrate scalability, offering capacities from 500 to 1,500 kilograms per hour. These machines feature low-noise operation, energy efficiency, and dual-shaft systems for high throughput. Enhanced automation, sensor-driven controls, and quick changeover capabilities allow operators to switch between different plastic types with minimal downtime. Energy-efficient designs and robust maintenance features further support flexible, cost-effective operations.

| Model | Capacity (kg/h) | Power (kW) | Key Features |

|---|---|---|---|

| JianTai XS-400 | 500 | 15 | Low noise, energy efficient |

| JianTai XR-800 | 1500 | 37 | High throughput, dual-shaft |

Real-World Capacity Planning Examples

Several companies have successfully scaled their recycling operations using new technology. Unilever and Alibaba, for example, deployed AI-powered closed-loop recycling machines in China, collecting over 500 metric tons of plastic with plans to expand further. AMP Robotics and Refiberd use AI and robotics to automate sorting and processing, increasing efficiency and throughput. These real-world cases highlight how advanced machines, combined with smart planning, enable organizations to meet growing recycling demands and support sustainability goals.

Energy Efficiency in New Technology Plastic Recycling Machine

Evaluating Power Consumption and Cost Savings

Energy efficiency stands as a top priority for any facility investing in a New Technology Plastic Recycling Machine. Modern machines deliver up to 30% greater energy efficiency than older models, resulting in significant electricity cost savings. For example, JianTai’s advanced systems can reduce annual electricity expenses by as much as $30,000. Operators also benefit from reduced material waste, as these machines enable the reuse of plastic scraps and lower energy consumption compared to producing virgin polymers. Using recycled plastic proves more cost-effective than relying solely on new materials, helping businesses cut operational costs and boost sustainability.

| Feature | Description | Impact |

|---|---|---|

| Energy Efficiency | 30% more efficient than older models | Electricity cost savings up to $30,000 annually |

Tip: Facilities should regularly monitor power usage to maximize cost savings and identify further efficiency improvements.

Latest Energy-Saving Technologies in 2025

Manufacturers in 2025 equip recycling machines with cutting-edge energy-saving features. Variable frequency drives (VFDs) optimize motor speeds, reducing unnecessary power draw. Smart sensors and AI-driven controls adjust processing parameters in real time, ensuring machines only use the energy required for each batch. Heat recovery systems capture and reuse waste heat, further lowering overall consumption. These innovations not only reduce utility bills but also extend equipment lifespan by minimizing wear and tear.

Environmental Impact and Compliance

New technology plastic recycling machines help companies meet strict international environmental standards. They support closed-loop recycling, sustainable product design, and reduced use of harmful substances. Machines comply with regulations such as the EU Green Deal, Ecodesign for Sustainable Products Regulation, and the EU Single-Use Plastics Directive. In the United States, they enable compliance with state-level mandates for recycled content and accurate labeling. By processing plastics efficiently and supporting proper documentation, these machines ensure environmentally sound management and help businesses avoid regulatory penalties.

| Regulation / Directive | Key Requirements Relevant to Plastic Recycling Machines in 2025 | Compliance Mechanism of New Technology Recycling Machines |

|---|---|---|

| EU Green Deal & Circular Economy Action Plan | Promote closed-loop systems, sustainable product design, reduce harmful substances, improve recyclability | Machines enable easier recycling, reduce environmental impact, support sustainable product design (ESPR compliance) |

| U.S. State-Level Packaging and Recycling Laws | Accurate labeling, recycled content mandates, EPR schemes | Machines help meet recycled content requirements, support labeling accuracy by enabling better sorting and recycling |

Automation and Technology Features in New Technology Plastic Recycling Machine

Smart Controls and Monitoring Systems

Smart controls and monitoring systems have transformed plastic recycling operations in 2025. Facilities now rely on real-time monitoring to track equipment performance and energy consumption. Operators use predictive maintenance to schedule repairs based on actual machine conditions, which prevents unexpected failures and reduces downtime. Automated parts ordering ensures that components arrive before breakdowns occur. Remote diagnostics allow experts to troubleshoot issues quickly, even from offsite locations. Centralized control systems oversee multiple machines, optimizing material flow and processing. These features help maintain consistent product quality and support compliance with customer requirements. Automated alerts and safety monitoring also improve worker safety by addressing hazards before they escalate.

Integration with Existing Operations

Modern recycling machines must fit seamlessly into existing workflows. Manufacturers design modular and scalable systems with plug-and-play components, making installation straightforward. Digital connectivity and IoT integration enable real-time data sharing between machines and business systems. This connectivity supports resource allocation, cost tracking, and customer service. Robotics, including collaborative robots, handle repetitive tasks and improve efficiency. Companies like Recycleye and Greyparrot use machine learning and computer vision to automate waste sorting, increasing sorting efficiency and reducing costs. These technologies help facilities adapt to labor shortages and maintain high productivity.

Upgradability and Future-Proofing

Facilities investing in a New Technology Plastic Recycling Machine seek long-term value. Manufacturers offer modular designs that allow easy upgrades as technology advances. Deep learning algorithms enable machines to self-adjust to changing waste streams, ensuring continued high performance. Digital twins and AI-driven automation support ongoing optimization and predictive maintenance. As regulations and plastic waste trends evolve, future-proof machines help companies stay compliant and competitive. This approach reduces operational costs and supports sustainability goals.

After-Sales Support for New Technology Plastic Recycling Machine

Warranty and Maintenance Agreements

A robust warranty and maintenance agreement protects the investment in a New Technology Plastic Recycling Machine. In 2025, manufacturers typically provide a comprehensive one-year warranty that covers all machines and parts against defects. This coverage gives buyers confidence in the reliability of their equipment. Maintenance agreements play a crucial role in controlling the total cost of ownership. Without proper management, repair and maintenance costs can unexpectedly increase expenses by 15%. Maintenance expenses often range from $5,000 to $15,000 per month, representing 5-10% of the equipment’s value annually. Proactive maintenance schedules and predictive strategies help minimize downtime and protect the machine’s longevity. Comprehensive agreements may include preventative maintenance, emergency repair response, and operator training, offering better long-term value and predictable costs.

Availability of Spare Parts and Technical Support

Top manufacturers in 2025 ensure global access to spare parts and technical support. They provide installation, routine inspections, cleaning, lubrication, and replacement of worn parts. Many companies offer 24/7 technical support and remote diagnostics, reducing downtime and keeping operations efficient. The scope and customization of after-sales services differ among suppliers. Some focus on on-site support and long-term maintenance, while others integrate advanced technology platforms for remote assistance. This broad coverage ensures that facilities can maintain high performance and regulatory compliance.

Training and Onboarding for Your Team

Effective training and onboarding programs maximize operational efficiency and extend equipment life. Leading manufacturers deliver hands-on training, virtual reality simulations, and online workshops. Programs like APR Design® Training & Tours and AIMPLAS’s Mechanical Recycling of Plastic Materials course combine classroom instruction with practical experience. These initiatives help operators understand machine operation, safety protocols, and troubleshooting. Comprehensive onboarding covers installation, maintenance best practices, and project coordination from order to operational checks. Updated training materials and flexible delivery methods ensure teams stay current with industry standards and product improvements.

A successful investment in advanced recycling equipment depends on careful evaluation. Facilities should review machine type, capacity, energy efficiency, automation, and after-sales support.

Thorough planning improves productivity and long-term value.

Checklist for buyers:

- Assess machine specifications and space needs

- Match capacity to current and future volumes

- Prioritize energy efficiency

- Confirm support and spare parts availability

- Plan for flexible, automated operations

FAQ

What types of plastics can new technology recycling machines process in 2025?

Most advanced machines handle HDPE, PET, PP, ABS, and PS. Some models process mixed or contaminated plastics using AI-powered sorting and chemical recycling technologies.

How often should facilities schedule maintenance for these machines?

Manufacturers recommend monthly inspections and quarterly preventative maintenance. Predictive systems alert operators to issues, reducing downtime and extending equipment lifespan.

Do these machines require specialized operator training?

Yes. Operators benefit from hands-on training, virtual simulations, and online courses. Proper training ensures safe operation, maximizes efficiency, and supports compliance with industry standards.

Post time: Jul-21-2025