The five main types of plastic granulator recycling granulator waste plastic recycling machine—Knife Granulator, Claw Granulator, Flat Cutter Granulator, Soundproof Granulator, and Central Granulator—are each designed to process specific forms of plastic waste, transforming them into uniform granules for reuse. By utilizing a plastic granulator recycling granulator waste plas, these machines significantly reduce the volume of plastic waste, lower emissions, and promote sustainable recycling practices, which is especially important as global recycling rates remain stagnant at around 9%.

| Type | Main Use |

|---|---|

| Knife Granulator | Cuts rigid plastics into fine, reusable granules using a plastic granulator recycling granulator waste plastic recycling machine |

| Claw Granulator | Handles tough, bulky plastic waste with a plastic granulator recycling granulator waste plas |

| Flat Cutter Granulator | Processes thin films and sheets efficiently with a plastic granulator recycling granulator waste plastic recycling machine |

| Soundproof Granulator | Minimizes noise during plastic size reduction using a plastic granulator recycling granulator waste plas |

| Central Granulator | Manages high-volume, industrial-scale recycling with a plastic granulator recycling granulator waste plastic recycling machine |

Key Takeaways

- Five types of plastic granulators—Knife, Claw, Flat Cutter, Soundproof, and Central—serve different recycling needs by efficiently processing various plastic wastes into reusable granules.

- Each granulator type offers unique eco-friendly benefits like energy savings, noise reduction, dust control, and support for large-scale recycling, helping reduce plastic waste and environmental impact.

- Choosing the right granulator depends on matching plastic waste types, recycling goals, and operational needs to ensure efficient, cost-effective, and sustainable plastic recycling.

Knife Granulator: Plastic granulator recycling granulator waste plastic recycling machine

How Knife Granulators Work

Knife granulators use high-speed rotating blades to chop plastic waste into small, uniform pieces. The machine’s design allows operators to adjust the angle and sharpness of the knives based on the type of plastic being processed. Open rotors work well for heat-sensitive plastics, while closed rotors handle thicker materials. Operators can control the output size with screens, ensuring consistent granulate. These machines often process scrap from injection molding, blow molding, and extrusion, making them a core part of any plastic granulator recycling granulator waste plastic recycling machine setup.

Best-Suited Plastic Waste

Knife granulators efficiently process a wide range of plastic waste, including:

- Sprues and rejects from manufacturing

- Film, profiles, and sheets

- Pipes such as HDPE and thin-walled types

- Automotive parts and bumpers

- Blow-molded products like PET and PP/PE bottles

- Canisters, buckets, and large containers

- Thermoformed and skeletal waste

- Thick-walled lumps and start-up waste

They adapt to various thermoplastics, including HDPE, PP, LDPE, and PE.

Key Recycling Advantages

| Feature | Knife Granulator Advantage |

|---|---|

| Material Versatility | Handles diverse plastics and shapes |

| Particle Size Control | Produces uniform granules, reduces fines |

| Maintenance | Fewer moving parts, easier upkeep |

| Environmental Benefit | Supports efficient recycling, lowers disposal cost |

Knife granulators stand out for their ability to deliver precise granulate size and easy maintenance, making them ideal for consistent recycling operations.

Eco-Friendly Features

Modern knife granulators include several eco-friendly innovations:

- Energy-efficient motors and enhanced rotor designs reduce power consumption by up to 30%.

- Smart sensors and AI-driven controls optimize processing and minimize waste.

- Durable blades require less frequent replacement, lowering resource use.

- Automated feeding systems and compact designs support sustainable facility layouts.

Tip: Regular maintenance, such as cleaning and lubrication, extends machine life and ensures optimal recycling performance.

Claw Granulator: Plastic granulator recycling granulator waste plastic recycling machine

How Claw Granulators Work

Claw granulators use a robust mechanism to break down hard plastics efficiently. The machine relies on a motor that drives claw-shaped blades at high speed. These moving blades work in tandem with fixed blades to cut and crush plastic materials. The process continues as the crushed particles pass through a screen, which ensures only granules of the desired size exit the system. Operators must maintain the machine properly to ensure optimal performance. Key operational steps include:

- The motor powers moving claw-shaped blades for high-speed cutting.

- Moving and fixed blades cooperate to break down plastics.

- Granules pass through a screen for size selection.

- Operators place the machine in a ventilated area to prevent overheating.

- Bearings require regular lubrication.

- Blade screws need tightening, especially after initial use.

- Blade sharpness must be checked frequently.

- The gap between blades should remain within recommended limits.

- Belt tension must be monitored and adjusted as needed.

Best-Suited Plastic Waste

Claw granulators excel at processing tough, rigid plastics that require aggressive cutting action. They handle materials such as ABS, nylon, and polycarbonate with ease. These machines are ideal for recycling hard and high-density plastic waste streams, including pipes, profiles, and packaging components. The following table highlights the suitability of claw blades compared to other blade types:

| Blade Type | Suitable Plastic Waste Streams |

|---|---|

| Claw Blades | Rigid, high-density, hard plastics such as HIPS, PC, ABS, PVC pipes and profiles, ABS components, PC water bottles, EPS/EPE packaging |

| Flat Blades | Flexible and low-density plastics |

| Flake Blades | PET bottle flakes, various sheets and profiles |

Key Recycling Advantages

Claw granulators offer several advantages for recycling operations. Their claw-shaped blades deliver high cutting efficiency, making them suitable for continuous, heavy-duty use. The design allows for easy maintenance and quick blade changes, reducing downtime. Operators benefit from consistent granule size, which improves the quality of recycled materials. The machine’s robust construction extends its service life, supporting long-term recycling goals.

Eco-Friendly Features

- Dust collection systems reduce airborne particles and improve workplace safety.

- Motor overload protection prevents unnecessary energy use.

- Staggered claw blades enhance cutting efficiency and extend blade life.

- Noise-reducing blade designs minimize energy loss and environmental impact.

- Quick-change blade structures support operational efficiency and reduce waste.

- Built-in cartridge dust collectors use pulse-jet filtration to capture debris and maintain clean air.

Note: Regular maintenance and proper operation of a Plastic granulator recycling granulator waste plastic recycling machine help maximize both efficiency and environmental benefits.

Flat Cutter Granulator: Plastic granulator recycling granulator waste plastic recycling machine

How Flat Cutter Granulators Work

Flat cutter granulators use a unique flat blade design to process plastic waste efficiently. The blades, made from high-strength CR12MOV steel, maintain a hardness of 57-59 degrees, which ensures durability during continuous operation. The main spindle holder, constructed from 45# steel with quenching treatment, provides additional strength. Internal hexagon screws with countersunk holes secure the blades, preventing wear over time. Many models feature a double-layer sound-insulated hopper, reducing noise in the recycling environment. Machines with higher horsepower include a chamber cooling system to dissipate heat, improving both efficiency and lifespan. Operators benefit from Siemens electrical components, which deliver stable performance and high safety standards.

Best-Suited Plastic Waste

Flat cutter granulators excel at processing bulky and thin plastics. The following table highlights their compatibility with various plastic waste types:

| Plastic Waste Type | Characteristics | Compatibility |

|---|---|---|

| PET bottles | Hollow, thin-walled | Highly compatible |

| HDPE containers | Hollow, thin-walled | Highly compatible |

| Films | Thin sheets | Suitable for uniform cutting |

| Sheets | Flat plastic sheets | Ideal for pelletizing |

| Sprues and runners | Production offcuts | Commonly processed |

| Scrap parts | Various plastic scraps | Suitable for size reduction |

| Shell plastics | Bulky, thin plastics | Optimized for these types |

Operators often pre-cut larger objects to fit the hopper, ensuring smooth operation. The flat cutter granulator prepares plastics such as PET, PP, PVC, PE, and ABS for further processing.

Key Recycling Advantages

- Flat cutter granulators produce uniform granules with minimal energy consumption, supporting both sustainability and cost-effectiveness.

- Their compact design fits small to medium-sized enterprises, allowing efficient granulation without large space requirements.

- Low maintenance needs reduce operational costs and streamline production.

- The machines offer easy operation and simple cutter replacement, improving workflow.

Tip: Electrical safety devices and overload protectors enhance operational safety, making these machines reliable for daily recycling tasks.

Eco-Friendly Features

Flat cutter granulators incorporate several eco-friendly technologies. Gravity-fed mechanisms and a horizontal flat-die configuration improve energy efficiency and process safety. The design eliminates the need for extra air filtering or explosion protection systems, reducing operational complexity and energy use. Improved bulk density of processed materials supports better recycling efficiency. These features reflect a commitment to sustainable recycling and help facilities lower their environmental impact.

Soundproof Granulator: Plastic granulator recycling granulator waste plastic recycling machine

How Soundproof Granulators Work

Soundproof granulators use advanced engineering to minimize noise during plastic recycling. Manufacturers design these machines with a fully enclosed structure that blocks noise propagation. Acoustic insulation materials line the interior, absorbing both noise and vibrations. Many models include vibration damping devices, such as anti-vibration feet, which reduce vibration noise and resonance. Some units feature a standard recycling device that prevents noise transmission during manual operations. For example, the WSGJ Soundproof Granulator employs a double-layer soundproof structure filled with high-quality acoustic cotton, keeping noise levels below 80 dB within one meter. The GSC Series granulators use a welded cutting chamber and integrated sound dampening housing, which further reduces operational noise while allowing easy maintenance.

Best-Suited Plastic Waste

Soundproof granulators handle a wide variety of plastic waste. They process both soft and hard plastics, including plastic films, woven bags, agricultural convenience bags, pots, barrels, beverage bottles, and furniture. These machines also manage rigid plastics, profiles, sprues, trims, lumps, rubber (specific grades), film and stretch plastics, raffia, big bags, ropes, cables, irrigation pipes, artificial grass, non-woven and geotextiles, PE briquettes, fiber bales, and tapes. This versatility makes them ideal for facilities that recycle mixed plastic waste streams.

Key Recycling Advantages

- Operators benefit from a quieter work environment, which improves safety and comfort.

- The fully enclosed design reduces noise pollution, supporting compliance with workplace regulations.

- Soundproof granulators maintain high efficiency in size reduction, ensuring consistent granule quality.

- The machines offer easy access for cleaning and maintenance, minimizing downtime.

Tip: Facilities that use soundproof granulators can operate in noise-sensitive environments, such as urban recycling centers or near residential areas.

Eco-Friendly Features

Soundproof granulators contribute to sustainable recycling practices. Their optimized, fully enclosed soundproof structure lowers noise emissions, reducing the impact on surrounding communities. Anti-vibration pads absorb vibration noise, which extends machine life and decreases maintenance needs. Optional features, such as cyclone dust separators and adjustable floor stands, further enhance operational efficiency. By integrating these technologies, a Plastic granulator recycling granulator waste plastic recycling machine supports both environmental protection and workplace well-being.

Central Granulator: Plastic granulator recycling granulator waste plastic recycling machine

How Central Granulators Work

Central granulators operate as the backbone of large-scale plastic recycling facilities. These machines use powerful rotating blades to cut and crush plastic waste into uniform granules. The main components include a feeding hopper, a cutting device, an eccentric roller, and a rotary knife. The staggered blade design increases cutting efficiency and allows the machine to handle hard or solid materials with ease. Central granulators often serve in centralized locations, processing waste or rejected parts from injection molding, blow molding, or extrusion lines. Industries such as automotive, electronics, home appliances, food production, and medical manufacturing rely on these machines for efficient recycling.

Best-Suited Plastic Waste

Central granulators excel at processing a wide range of plastic waste types. The following table highlights their efficiency with different materials and blade types:

| Plastic Waste Type | Blade Type | Efficiency Notes |

|---|---|---|

| Thick sprues, rigid plastics | Teeth blades | High cutting efficiency for tough materials |

| Thin-walled items (bottles, tubes) | Paddle blades | Lower energy use, better for thin plastics |

| Hard shells, solid materials | Staggered blades | Distributes workload, improves cutting efficiency |

| Large volumes of plastic waste | N/A | Ideal for heavy-duty, high-capacity recycling |

Operators use central granulators to process rejects, runners, sprues, pipes, profiles, bags, bottles, bales, buckets, tubs, film, fiber, containers, drums, and IBCs.

Key Recycling Advantages

- Central granulators enable efficient recycling by breaking down large plastic waste into smaller, reusable pieces.

- The machines support continuous operation, making them suitable for high-volume industrial environments.

- Staggered rotating blades improve cutting performance and extend machine life.

- Centralized processing reduces manual handling and increases overall productivity.

Tip: Regular maintenance of the cutting device and feeding system ensures consistent granule quality and machine longevity.

Eco-Friendly Features

Central granulators contribute to sustainable manufacturing by reducing plastic waste sent to landfills and oceans. They recover and reuse defective products and production scrap, minimizing resource loss. Many models include dust separation systems that improve air quality and product purity. Low-noise granulation options and advanced soundproofing technology create safer work environments. Metal detection and separation accessories prevent contamination, while overload protection and shockproof pads extend machine life. These features help facilities using a Plastic granulator recycling granulator waste plastic recycling machine lower their environmental impact and support a circular economy.

Comparison Table: Plastic granulator recycling granulator waste plastic recycling machine

Granulator Types and Uses

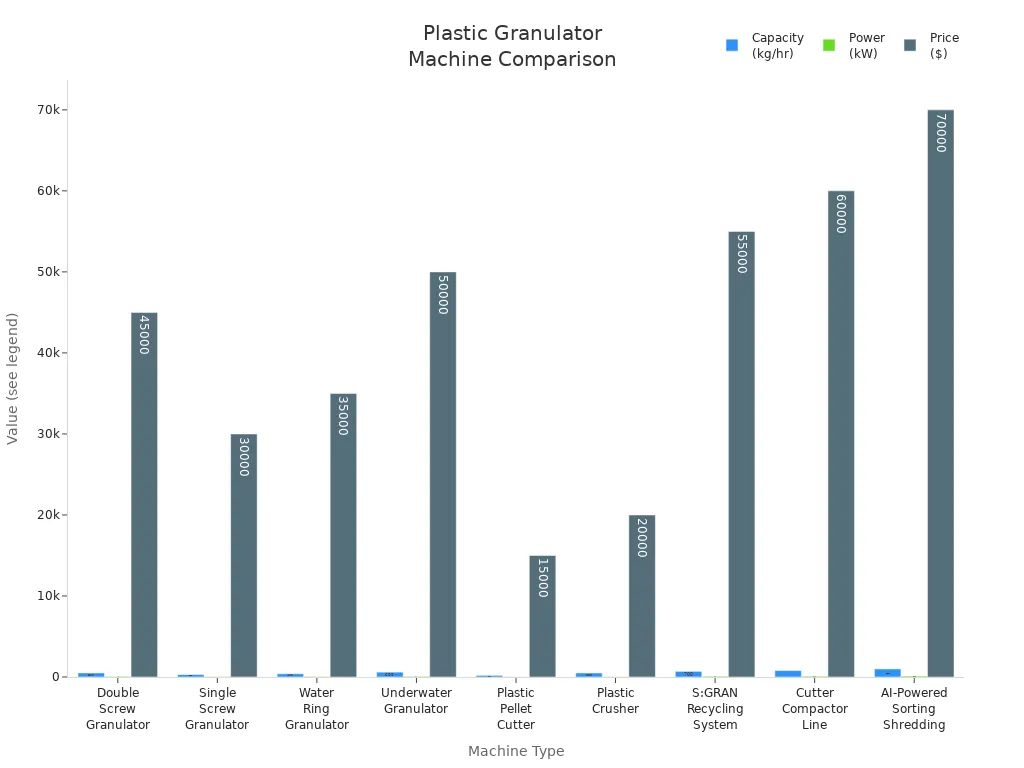

Selecting the right granulator depends on several key performance metrics. These include output quality, capacity, material compatibility, technology, maintenance, and cost. The following table summarizes the main types and their typical applications:

| Granulator Type | Typical Use Cases | Capacity (kg/hr) | Power (kW) | Unique Features |

|---|---|---|---|---|

| Knife Granulator | Rigid plastics, automotive parts, bottles | 500-800 | 55-75 | Adjustable blades, uniform granules |

| Claw Granulator | Bulky, hard plastics, pipes, profiles | 600-900 | 75-80 | Robust claws, high throughput |

| Flat Cutter Granulator | Films, sheets, thin-walled containers | 400-600 | 50-60 | Flat blades, low energy use |

| Soundproof Granulator | Mixed waste, noise-sensitive environments | 300-500 | 40-55 | Enclosed design, reduced noise |

| Central Granulator | Industrial-scale, continuous recycling | 800-1200 | 90-100 | Staggered blades, automation options |

Performance metrics such as particle uniformity (±5% to ±1%) and intelligent control systems (from basic PLC to AI optimization) further distinguish each Plastic granulator recycling granulator waste plastic recycling machine.

Eco-Friendly Benefits

Each granulator type offers unique environmental advantages. Central granulators enable continuous, high-volume recycling, which reduces landfill and ocean waste. Knife and claw granulators conserve resources by processing tough plastics efficiently, lowering the need for new materials. Flat cutter granulators minimize energy consumption and dust, supporting cleaner operations. Soundproof granulators reduce noise pollution, improving workplace safety and community well-being.

| Granulator Type | Eco-Friendly Benefits |

|---|---|

| Knife Granulator | Lowers disposal costs, supports efficient recycling |

| Claw Granulator | Reduces airborne dust, extends blade life |

| Flat Cutter Granulator | Improves energy efficiency, reduces operational complexity |

| Soundproof Granulator | Minimizes noise emissions, supports urban recycling |

| Central Granulator | Reduces landfill waste, supports circular economy |

Operators should consider both output capacity and environmental impact when choosing a granulator for sustainable recycling.

How to Choose the Right Plastic granulator recycling granulator waste plastic recycling machine

Assessing Your Plastic Waste

Selecting the right recycling machine starts with a thorough evaluation of the plastic waste stream. Operators should:

- Identify the main types of plastics present, such as PET, HDPE, PVC, LDPE, or PP, since each material may require a different processing approach.

- Audit incoming waste to determine dominant polymer types and contamination levels.

- Estimate daily and projected waste volumes to match machine capacity with operational needs.

- Evaluate the desired output quality to ensure the recycled material meets manufacturing standards.

- Consider machine efficiency and power consumption to balance throughput with operational costs.

- Check for versatility, as some machines can process multiple plastic types, increasing flexibility.

- Review safety features and maintenance requirements to minimize downtime and extend equipment lifespan.

Tip: Understanding the specific processing needs of each plastic type helps prevent operational inefficiencies and environmental issues.

Matching Granulator to Recycling Goals

Recycling goals play a critical role in machine selection. Facilities aiming to reduce virgin resin use or improve sustainability should prioritize machines that deliver high efficiency and consistent output. For example, a central granulator can help a plant cut virgin resin purchases by 40% within six months, while a heavy-duty granulator enables daily recovery of thousands of pounds of material. These machines support on-site processing, reduce transportation emissions, and help companies meet environmental and social governance (ESG) targets. Choosing the right Plastic granulator recycling granulator waste plastic recycling machine aligns recycling operations with business objectives and regulatory requirements.

Practical Selection Tips

Operators can follow these practical tips to ensure the best fit for their recycling needs:

- Match production capacity to business scale; small operations may benefit from mid-range granulators, while large facilities require industrial models.

- Prioritize energy-efficient models to lower electricity costs.

- Select machines with durable components, such as hardened steel cutters, to reduce maintenance frequency.

- Look for automation features like automatic load detection to maintain consistent output and reduce waste.

- Choose machines that offer granule size options to meet specific end-product requirements.

- Evaluate after-sales service and support for long-term reliability.

- Ensure compliance with environmental standards and workplace safety regulations.

| Environmental Impact Aspect | Explanation |

|---|---|

| Product Contamination | Using the wrong machine can reduce product purity, leading to more waste. |

| Dust and Air Pollution | Inadequate dust control increases air pollution and health risks. |

| Energy Consumption | Inefficient machines raise electricity use and environmental footprint. |

| Waste Generation | Poor-quality granules result in higher rejection rates. |

| Material Compatibility | Mismatched machines cause operational issues and reduce sustainability. |

Selecting the right Plastic granulator recycling granulator waste plastic recycling machine ensures efficient recycling of plastics like bottles, films, and rigid parts. Operators should match machine type to waste stream and consider factors such as energy efficiency, granule size, and maintenance.

| Consideration | Impact on Recycling |

|---|---|

| Material Compatibility | Ensures optimal output |

| Energy Efficiency | Lowers costs, emissions |

| Maintenance | Extends machine life |

Choosing wisely supports sustainability and reduces environmental impact.

FAQ

What plastics can a granulator process?

Most granulators handle PET, HDPE, PVC, LDPE, and PP. Operators should check machine specifications for compatibility with specific plastic types.

How often should operators maintain a granulator?

Operators should inspect and clean the machine weekly. Blade sharpening and lubrication depend on usage frequency and material hardness.

Why choose a soundproof granulator?

Soundproof granulators reduce workplace noise. They help facilities meet safety standards and improve operator comfort.

Post time: Aug-04-2025